Maximize safety and performance

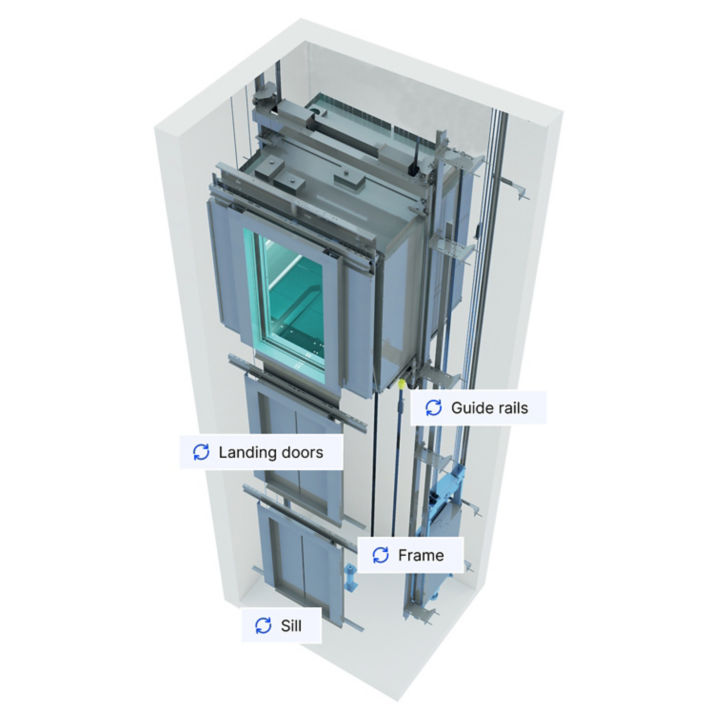

New elevators have advanced hoisting and controller technology, like regenerative drives. This means you'll see significantly lower running costs, top-notch performance, and peace of mind knowing everything meets regulations.